Motor Hall Sensor Tuning

Introduction

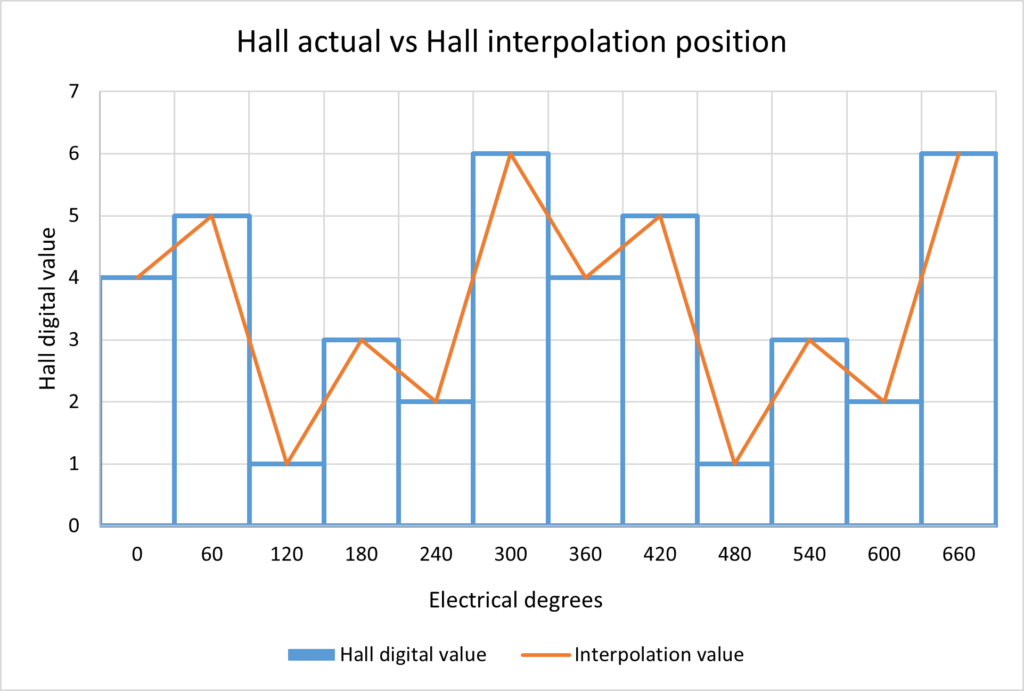

The Hall interpolation start frequency corresponds to the Hall sensor frequency above which starts interpolating rotor angle transitions to form a smooth triangle wave based on interpolating the time between Hall sensor edges instead of the six-step Hall transitions. The interpolation is averaged over the number of Hall Interpolation Transitions. Hall interpolation stops interpolating below the Hall interpolation stop frequency.

Tuning

The parameters can be used to reduce the chatter and noise associated with Hall sensor commutated motors when operating at low speeds. Typically, the Hall interpolation start frequency is set at twice the value of the Hall interpolation stop frequency to prevent rough motor operation. It is recommended that the lower the interpolation frequencies can be set the better. This is particularly true with high pole count direct drive motors.

This tuning process is iterative and will require some trial and error in order to get it to feel right. The most important factors in determining how much chatter can be felt at low speeds are system backlash like spoke tightness and how much power the controller is providing to the wheel. For some applications, it is not possible to completely eliminate low-speed chatter.

Setting Hall interpolation start frequency and Hall interpolation stop frequency above the expected peak motor electrical frequency, effectively disables this feature.

Configuration Parameters

| Name | Description | Units | Address |

| 128 | |||

| 88 | |||

| 89 |